Scheme of the stove vaz 2110 and functional features

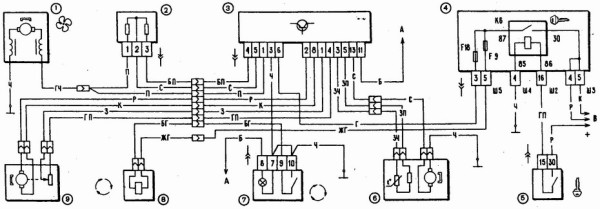

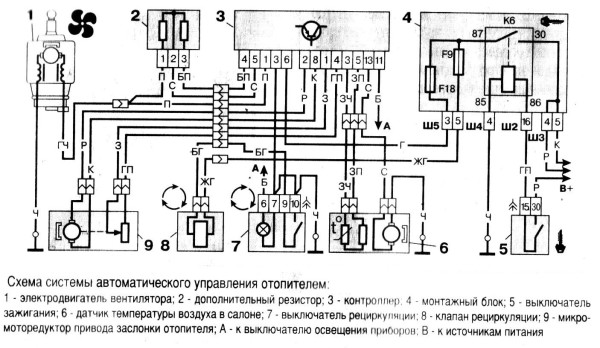

Scheme of the heater vaz 2110

As you know, the main functional purpose of a car stove is to supply warm or cold air into the passenger compartment. In order to have a practical opportunity not only to identify a malfunction, but also to eliminate it, you need to know how the scheme of the VAZ 2110 stove is arranged.

After all, there are a variety of options for possible malfunctions and there can be both malfunctions in the electrical circuit, and in one of the elements of the furnace itself itself. On the VAZ 2110, the scheme of the stove and its knowledge will make it easier for the motorist to find the cliff and repair the heater.

The main reasons for the poor performance of the electric furnace

Before you can directly start looking for a solution to a problem, you need to be able to quickly and effectively identify it. First, it is advisable to consider the general scheme of the structure of the furnace.

So, the heater furnace consists of the following components:

- mounting block fuse;

- incendiary lock;

- ignition switch together with its unloading relay;

- a special switch that regulates the operating mode of the furnace electric motor;

- additional built-in resistor;

- heating the rear window of the car, which contains the adjusting key of the heater with a light indicator;

- a special functional element for glass heating.

One of the reasons for the malfunction of the electronic circuit of the furnace may be the lack of functional activity at both low and high speeds.

In this scenario, you must proceed as follows:

- first you should make sure that the fuse has not accidentally blown;

- If a blown fuse is found, it will need to be replaced with a new one as soon as possible.

Note.

Before proceeding directly to replacing the old fuse with a new fuse, it is necessary to first and without fail establish the cause of the burnout. If this is not done, then the life of the new fuse is likely to be short.

- there may also be a break or damage to the wiring at the junction;

- in order to exclude the above reason, it is necessary to check the electrical circuit according to the furnace diagram;

- after which, it is necessary to eliminate the impulse, if it took place;

- if the heating switch does not function, then the most likely cause is sticking of the pusher or burnt contacts;

- to accurately diagnose a switch malfunction, you need to check the voltage level at the side terminals while changing the position of the switch in space (for this, it is enough to apply current to the main terminal);

- if during the diagnostics a change in voltage is not established when the position of the switch knob is changed, then it must be urgently replaced;

- there are a huge number of possible reasons for leaving the working functional state of the electric motor: breakage of electrical connections or anchor winding, immobilized cleaning brush, oxidation and / or pollution of the anchor collector;

- it is not difficult to revive the movements of the brush, it is enough to disassemble and then clean them;

- it is also not difficult to restore the wires, because the main thing is to find the localization of the defect;

- if several of the above provisions did not work, then there is only one way out - a complete replacement of the heater electric motor;

- sometimes, which is extremely rare, the cause of the malfunction may be the mounting block;

- there are many reasons for the failure of the mounting block, but the main ones are: at the place of soldering, a complete or partial rupture of the electrical circuit, ignition of current-carrying tracks;

- the circuit should be checked according to the furnace diagram, otherwise it will be simply impossible to detect breaks and malfunctions;

- the final practically probable cause may be an internal break in the circuit of the auxiliary (additional) resistor (see);

- to exclude a malfunction associated with the operation of the resistor, it is necessary to check its circuits.

The decrease in the anchor rotations in the electric motor is one of the causes of a malfunction in the general scheme of the furnace.

In this case, it is necessary to be able to find and eliminate micro-causes, and in particular:

- in case of clogging or oxidation of the armature of the collector system, the number of rotations of the electric motor will also be reduced;

- to eliminate the above problem, you will need to perform a general cleaning of the collector system;

- sometimes a short circuit may occur in the area between the turns of the armature winding, and in order to exclude this cause, it is necessary to check the amount of incoming current;

- everything is very simple, if the closure of the turns takes place, then the input current strength will exceed 4.5A;

Note. It is necessary to measure the incoming current only after a preliminary check of the objectivity of the ammeter readings.

What does extraneous noise in the heater electric motors testify to and what is its role in the general circuit

If there is sound in the furnace, then most likely the cause of extraneous noise is a malfunction of the impeller, which is touched by the deflector during operation. This means that the deflector was not installed correctly, most likely as a result of a factory defect.

In this case, to correct the operation of the furnace electric motor, simply put the deflector in the desired (correct) position.

Note. When buying any part in a car service, you need to pay attention to whether the seller provides a guarantee of the age of money if the product does not fit for some reason.

To summarize, it should certainly be noted that the device of the general scheme of the furnace is very simple, however, there are a huge number of various nuances. Photo - materials must be used in order to understand the general scheme, video for a practical understanding of do-it-yourself troubleshooting.

And the instruction takes time to comprehend. The cost of repair depends on the particular case of the malfunction.