Sealant for metal doors: selection and installation

To provide additional sound insulation, any metal doors require the installation of a seal. This article will tell you how to choose and correctly install a high-quality sealant for metal doors.

General concept and functions of a seal for a metal door

Sealant - a fitting element of a metal door. The main function of the seal is to protect the room from the ingress of extraneous sounds. Additional functions of the seal:

- protection of the premises from foreign odors;

- thermal protection - prevention of drafts;

- sealing - ensuring a snug fit of the door leaf to the door frame.

Consider the basic requirements for a high-quality seal for a metal door:

- the seal must ensure complete tightness, the door protects the room from extraneous noise, moisture, cold air, fine dust particles or strong odors;

- the seal ensures reliable and smooth closing of the door;

- the seal must meet high standards that provide water and air tightness and excellent cushioning properties of a metal door;

- the seal eliminates the sharp unpleasant sounds that a metal door makes when closing; after installing the seal, the door closes softly and silently;

- the seal for a metal door must be resistant to sudden changes in temperature in order to avoid hardening or peeling off;

- the seal should interact well with the door; when closing, there should be no gaps;

- ensuring fire safety: using a rubber contour to trap cold smoke, using an intumescent layer to fill gaps and prevent the spread of fire.

Varieties of seals for a metal door

Depending on the type of material, the seal is divided into:

- rubber,

- silicone,

- polyurethane,

- plastic,

- foam.

The rubber seal for a metal door is characterized by durability and endurance.

Advantages of installing a rubber seal on a metal door:

- high level of air and moisture resistance;

- resistance to prolonged exposure to precipitation, temperature changes, ultraviolet;

- long service life;

- low cost;

- no cracking.

Rubber seals are made of oil-resistant, acid-resistant rubber, which has a food or high-tech quality.

Not inferior to rubber and silicone seals, which are great for metal doors. The advantage of a silicone sealant is that silicone does not emit harmful substances and ensures the environmental safety of the home. Silicone does not provoke the appearance of allergies, therefore, such seals are installed on metal doors in children's or medical institutions.

The polyurethane sealant is easily attached to the door, as it has a self-adhesive film on one side. Plastic seals are rarely installed on metal doors, as well as foam rubber. Although the cost of these seals is quite low, the quality characteristics do not allow such seals to be used on a metal door for a long time.

In relation to the design and type of fastening, seals are divided into:

- magnetic seal for metal doors;

- sealant with additional clamping mechanism;

- sealant for metal doors self-adhesive.

The magnetic seal appeared not so long ago, but is increasingly used in the manufacture of metal doors from the manufacturer. Magnetic seals are installed on the doors of the refrigerator or freezer. The principle of operation of the seal is based on the attraction of permanent magnets with the help of attraction poles. A triple circuit of a magnetic seal is installed on metal doors. The first two circuits are located directly on the door, and the third - on the door frame. Magnetic seals have a disadvantage: if there is a strong attraction of magnets, it will be difficult for a child or an elderly person to open such a door, and if there are weak magnets, the door will not meet all the requirements for sealing and sound insulation.

It is better to install a magnetic seal on metal doors that do not have decorative elements, but consist of ordinary metal sheets. The magnetic seal has two components: a soft part and a magnetic insert. The soft part is made of thermoplastic elastomer. Advantages of using thermoplastic elastomer:

- resistance to aging;

- operating temperature from -65 to +90 °C;

- after use, the material is recycled.

1. When choosing a self-adhesive seal, be sure to check the expiration date of the adhesive that is applied to one side of the tape.

2. Do not use foam seals for a metal door. Indeed, as a rule, a metal door is used at the entrance to the room and has the greatest load in terms of the number of openings, in this case the foam rubber will deteriorate very quickly.

3. Before giving preference to a certain sealant, carefully study the information about the materials, expiration date and technical features of the sealant.

4. To check the sealing properties of the seal, press the seal a little, if the material recovers quickly, the seal will provide a good seal.

5. When choosing a seal that requires additional bonding, buy a good quality silicone adhesive.

6. Pay attention to the color of the seal, in most cases it is black, brown or white, but there are exceptions and some companies allow you to choose the color individually for the color of the door.

7. When choosing a seal for an entrance metal door, one should not be guided by the color variety, since the paint significantly affects the quality characteristics of the seal, it is better to choose a standard black seal.

8. The rubber seal should be of medium hardness, too soft material will quickly become unusable, and too hard seal will prevent the door from closing.

9. When choosing a self-adhesive sealant, the sticky side should be covered with fine glass fiber particles.

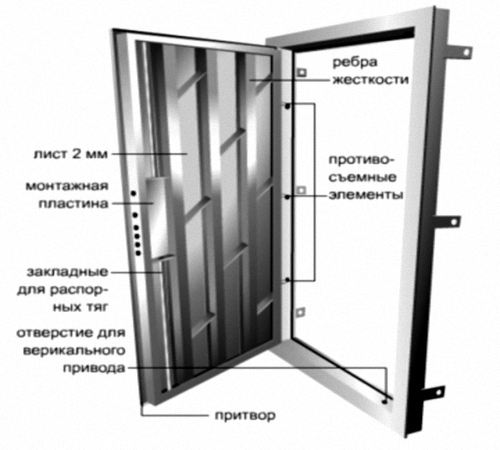

![]()

Rules for selecting a seal for a metal door

Before you buy a seal for metal doors, you should decide on the shape and type of seal. Seals are sold in roll form with an average tape length of 600 cm, for a standard door this seal will be enough.

To choose the right seal, you need to measure the gaps of the metal door. For this procedure, take plasticine, which must be wrapped in polyethylene and inserted into the slot, with the door closed. Using a tape measure or ruler, measure the length of the gap.

For a gap that ranges from 1 to 3 mm, a foam rubber, polyethylene foam or polyvinyl chloride sealant of a rectangular shape is used.

For gaps that exceed 3 mm, rubber seals are used, which are divided into:

- seals with a C-shaped, K-shaped or E-shaped profile - used in three-millimeter gaps;

- A P-shaped or V-shaped seal is used to eliminate a gap with a thickness of 3 to 5 mm;

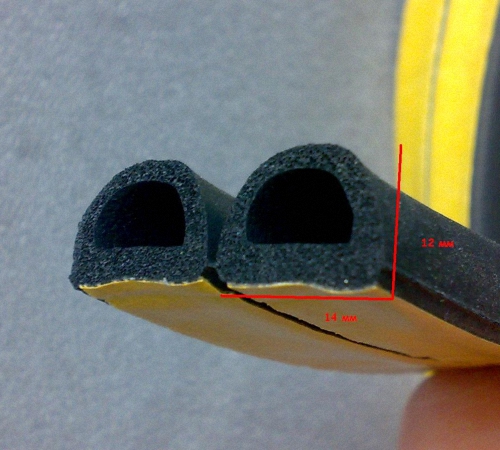

- in gaps that exceed 5 mm, an O-shaped or D-shaped seal is installed.

When performing work on replacing the seal, you should tear off a piece of the old seal and pick up a new seal that is as similar in size as possible in the store.

To determine the size of the required sealant, determine the number of layers, and then measure the dimensions of the metal door and determine the perimeter of the door frame, multiply the resulting number by the number of layers. It is better to purchase a seal with a margin.

Installing a seal on a metal door

1. When replacing the seal, carefully clean the surface of the doors from the old seal with fine sandpaper and wash the doors well with acetone or alcohol solution.

2. Metal doors are used at the entrance to the room, so it is advisable to install two or three layers of sealant to ensure more reliable sealing.

3. When installing a seal on the entrance door to an apartment that does not face the street, install two layers of seal. Lay the first layer on the outer door leaf, and install the second on the door frame.

4. If the seal is installed on a metal door that goes directly to the street, it is better to lay three layers of seal. The first and second circuits are installed on the door frame and the inside of the door, and the third - on the outer surface of the door. Requirements for an external seal for a metal door: resistance to temperature extremes, ultraviolet radiation, moisture, precipitation, good dimensional stability and tightness.

5. When buying branded doors from the manufacturer, there is a seal on such doors. In the presence of a double porch of the door, the seal is located on each porch.

6. The rubber seal is installed using silicone adhesive. To do this, the sealant is gradually smeared with glue and applied to the surface of the door.

7. When installing the seal on a painted metal door, at least twenty days must pass from the moment of painting.

Installation of a self-adhesive seal

Before replacing the seal, clean the surface of the remnants of the old seal and wipe the doors with an acetone solution.

A self-adhesive seal is even easier to install than a rubber one. For installation, you need to gradually, removing the tape, glue the seal around the perimeter of the door leaf. If the seal begins to stick poorly over time, use glue or sealant for gluing. When replacing the seal, do not use separate pieces, as there is a risk of poor sealing functions by the seal. Pay attention to the sealing of the corners, as in these places wrinkling or poor-quality gluing of the sealant is possible. After complete gluing of the seal, cut off the remnants with scissors.

Overview of manufacturers of seals for a metal door

1. Deventer (Germany)

Peculiarities:

- use of environmentally friendly materials for the manufacture of sealant;

- availability of certificates of compliance with international standards;

- excellent recovery properties after compression of the seal;

- the use of a thermoplastic elastomer, which prevents the aging of the seal due to exposure to ultraviolet radiation.

2. Stomil Sanok (Poland)

Peculiarities:

- high level of wear resistance;

- additional sealing circuit;

- production of a rubber sealant from special microporous rubber;

- resistance to temperature changes from -44 to +66 ° C;

- softness and high elasticity of the seal;

- service life from seven to ten years;

- the seal ensures noiseless closing of the metal door.

3. Akord (Turkey)

Peculiarities:

- service life of 5 years or more;

- harmlessness and environmental friendliness;

- prevention of dust, sound or foreign odors entering the room;

- affordable cost.

4. Welless (Germany)

Peculiarities:

- variety of colors: black, beige, transparent, white, brown, dark brown;

- ensuring maximum density and silent closing of a metal door;

- high performance with temperature changes;

- resistance to chemical influences;

- antitoxicity, involves the use of a sealant in medical institutions.

5 Varnamo (Sweden)

Peculiarities:

- the use of porous rubber for the manufacture of self-adhesive seals;

- a variety of forms of seals: K-shaped, P-shaped and D-shaped;

- minimum service life of seven years;

- ease and simplicity of installation of a sealant;

- rolls are sold in convenient packaging of 6, 16, 24 and 100 meters.

6. Cyclone (Switzerland)

Peculiarities:

- moisture and wind resistance;

- heat resistance from -40 to +60 °C;

- good adhesion of the self-adhesive sealant;

- provides excellent tightness and silent closing of a door.